Air Water Inc., announced today that it has acquired M1 Engineering (M1), a leading global provider of specialized cryogenic distribution equipment based in Bradford, West Yorkshire (England).

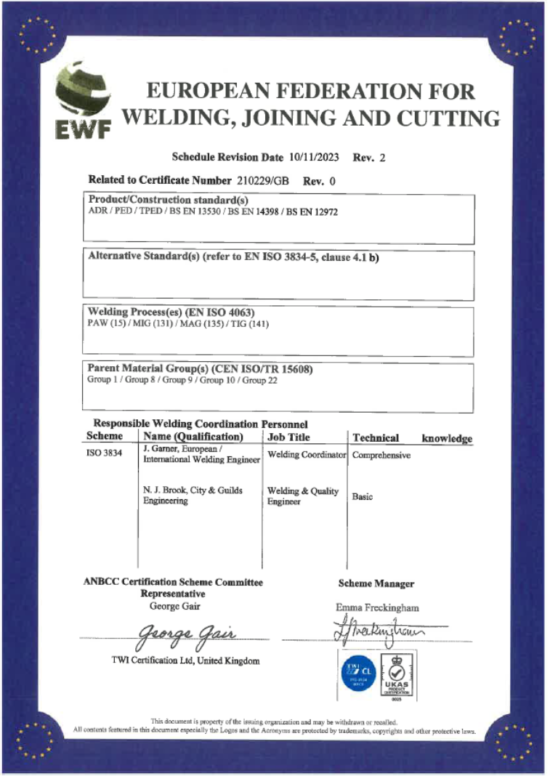

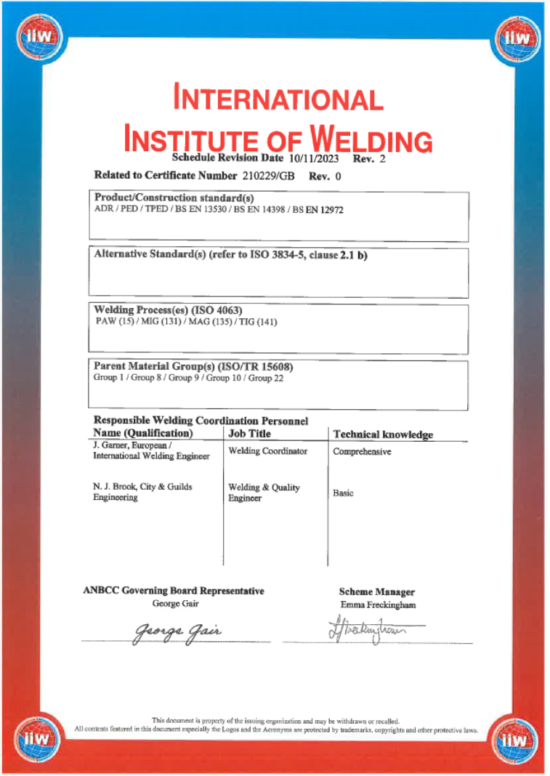

Founded in 1973, M1 enjoys a global reputation at the forefront of cryogenic distribution technology and development with complete product offering in atmospheric gasses, specialty gases, and LNG. Products include semitrailers, microbulk rigid units and ISO tank containers. Additional capabilities also include Bespoke Cold Boxes for mini air separation plants to provide on demand air gases.

“North America and Europe are key growth areas for Air Water Inc. globally. Over the past 5 years Air Water has made significant investments in cryogenic equipment producers acquiring Taylor-Wharton (TW), TOMCO2 Systems, Cryogenic Vessels Alternative (CVA), Cryofin, CO2 Air (equipment only), AMCS Corp and stake in Dohmeyer Cryogenics. M1 is strategically positioned, with the compliment of Taylor-Wharton’s advanced technology in hydrogen distribution and refueling, to lead the build out of the European Hydrogen Infrastructure that will be required to support the continued growth of Fuel Cell Electric Vehicles (FCEV) while further expanding footprint in Microbulk, CO2, and atmospheric transports”, states Eric Rottier, COO of Air Water America and CEO of Taylor-Wharton and TOMCO2 Systems.

Jason Gill, Managing Director of M1 notes, “In what is M1 Engineering’s 50th year anniversary of trading, this transaction marks a historic milestone for the company. We’re excited for the opportunity to collaborate and grow with the Air Water America team to further enhance our product offering in hydrogen as the European market continues to expand. This acquisition enables M1 to access greater resources, products, and technology that will continue the long tradition of superior quality and technology that the M1 brand represents.”

About Air Water Group

Air Water America is a wholly owned subsidiary of Air Water Inc. (“Air Water Japan”). Air Water Japan was established in 1929 and, for over 90 years, has continued to grow in the manufacturing and supply of industrial gases and related services. Air Water Japan has developed its own engineering capability to design, manufacture and operate air separation units and non-cryogenic air separation plants. Air Water Japan has successfully managed our industrial gas businesses and expanded our product supply and service capability throughout Japan, becoming a strong No. 2 player in the market. In the past few years, Air Water Japan also invested outside of Japan, in the U.S., India, and Asian markets.

Since its incorporation, Air Water Japan and its group entities (“Air Water Group”) have expanded its businesses and provided consistent growth in revenues. Air Water Japan’s common stock is listed on the Tokyo Stock Exchange and Sapporo Stock Exchange. Air Water Group employs more than 19,000 people around the world and has annual net sales of approximately JPY888 billion (equivalent to USD 7.4 billion) on a consolidated basis for the fiscal year ended March 31, 2022.

visit our website at www.awi.co.jp/en/index.html

Contacts

________________________________________

Media Relations

Jeff Holyoak

Jholyoak@tomcosystems.com

+1 404-323-7153